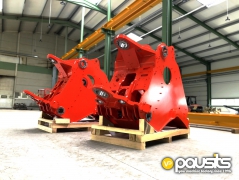

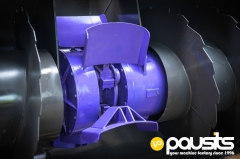

Painting

Following current trends, our goal is to manufacture products with the highest added value, an essential part of which is painting after priming. The first impression of the products we deliver to our partners is given by the paint finish, which is why the application of painting technologies that meet the requirements of the 21st century is of outstanding importance.

The 40-meter-long paint line consists of five cabins, each designated for washing, drying, preparation, priming, and painting, as well as drying at the appropriate temperature. The paint line also includes a lower and upper conveyor track, which greatly facilitates and speeds up material handling, saving both time and energy. The cabins are capable of painting products up to 6,000 kg in weight, 6,000 mm in length, 3,000 mm in width, and 2,500 mm in height. The proper mixing ratios are ensured by two Promix-type mixing tanks. A separate closed settling system has been installed to recycle the wastewater generated in the washing cabin, where the filtered washing water is returned for reuse. The painting cabin complies with the strictest environmental, fire safety, and occupational health and safety regulations.