Robot welding

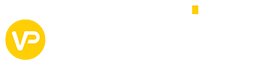

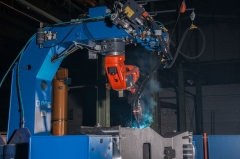

In 2014, Verarbeiten Pausits Kft. purchased three welding robots to accelerate order fulfillment and address the growing shortage of skilled labor. Our goal is clear: we aim to reduce the welding time of products made in series production, while also improving the quality of work. With the introduction of the welding robots, we redirected our certified welders to the production of custom products. In addition to single-wire welding, our robots are equipped with a tandem welding option, as well as touch sensors, arc sensors, and iCSE LD offline sensors.

Two of our welding robots are capable of movement on 13 axes simultaneously. The "L" shaped turning devices can hold products weighing up to 5,000 kg. The robots have four arms, each of which can cover a working area with a 5,000 mm diameter. The third (longitudinal axis) welding robot can move on 9 axes. The two turning devices associated with this robot have a clamping length range of 3,000 mm to 10,500 mm and a load capacity of 6,000 kg. These turning devices can rotate 360 degrees. Each robot arm is paired with two workstations to ensure maximum utilization. The work areas are separated by protective walls, ensuring continuous operation, even in automatic welding mode.